What Is Warehouse Racking Used For?

Warehouse racking is a systematic approach to organizing and storing goods in vertical shelves or structures to optimize space, accessibility, and safety. When it comes to storing rubber products like rubber sheets, silicone sleeves, O-rings, hydraulic seals, and industrial rubber components, warehouse racking plays a crucial role in maintaining product quality and minimizing damage during storage.

- Organizing rubber sheets by type and thickness

- Storing silicone tubes and hoses on vertical reels

- Pallet racking for boxed rubber goods

- Bin shelving for small components like O-rings and seals

What Are the Different Types of Warehouse Storage Solutions?

- Selective Pallet Racking

- Drive-In & Drive-Through Racking

- Cantilever Racking

- Push Back Racking

- Carton Flow Racks

- Heavy Duty Industrial Racking

The most common system, allowing easy access to every pallet. Ideal for fast-moving rubber inventory stored on pallets.

These systems are designed for high-density storage of similar rubber products. Suitable when there are large quantities of the same SKUs.

Perfect for storing long or bulky rubber products like rubber rolls, silicone tubes, or industrial hoses.

Allows storing multiple pallets deep with last-in, first-out (LIFO) rotation. Useful for medium-turnover rubber materials.

Used for lightweight rubber products or components. Incorporates gravity-fed rollers for easy access to smaller items.

Designed for robust load-bearing requirements. Ideal for storing dense rubber blocks, bulk-packed items, or industrial storage racks filled with various rubber parts.

What Are the Different Types of Warehouse Storage Solutions?

Implementing a warehouse racking system for rubber products offers several operational and logistical benefits:

- Space Optimization: Vertical stacking makes the best use of floor space, especially in high-volume rubber product warehouses.

- Product Safety: Properly racked storage helps avoid material deformation, especially in rubber sheets and silicone rolls that are prone to creasing or compression damage.

- Improved Accessibility:Well-organized storage racking systems allow for quicker retrieval of products like O-rings, seals, and rubber mats, improving overall warehouse productivity.

- Inventory Accuracy: Racking systems promote clear labeling and categorization—helping with cycle counts, FIFO implementation, and restocking efficiency.

- Reduced Material Waste: Storing rubber products under structured racked storage conditions reduces wear and minimizes exposure to contaminants like oil, dust, and UV light.

- Worker Safety: Industrial pallet racks are designed to reduce manual handling and improve load stability, reducing workplace accidents.

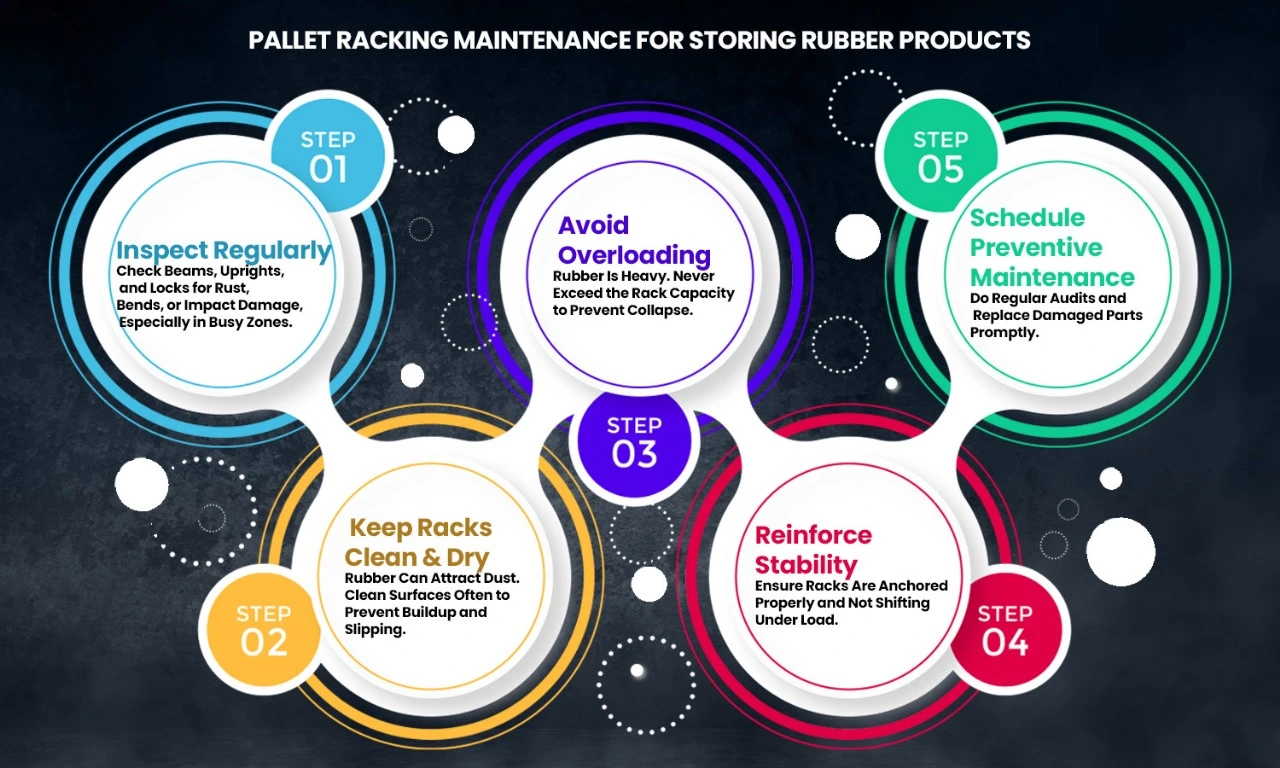

What Maintenance Does Pallet Racking Need for Storing Rubber Products?

- Inspect Regularly for Damage

Check beams, uprights, and locking pins for signs of corrosion, impact, or bending—especially around high-traffic zones.

- Keep Racks Clean and Dry

Rubber sheets and components can attract dust and residue. Clean shelving surfaces and rubber contact points regularly to prevent buildup or slippage.

- Avoid Overloading

Respect the load-bearing capacity of pallet warehouse racking. Rubber products can be deceptively heavy, especially when stacked.

- Reinforce Anchoring & Stability

Verify that all industrial racking systems are securely anchored and not shifting under heavy loads.

- Schedule Preventive Maintenance

Include inspections in warehouse audits, and ensure damaged components are replaced promptly.

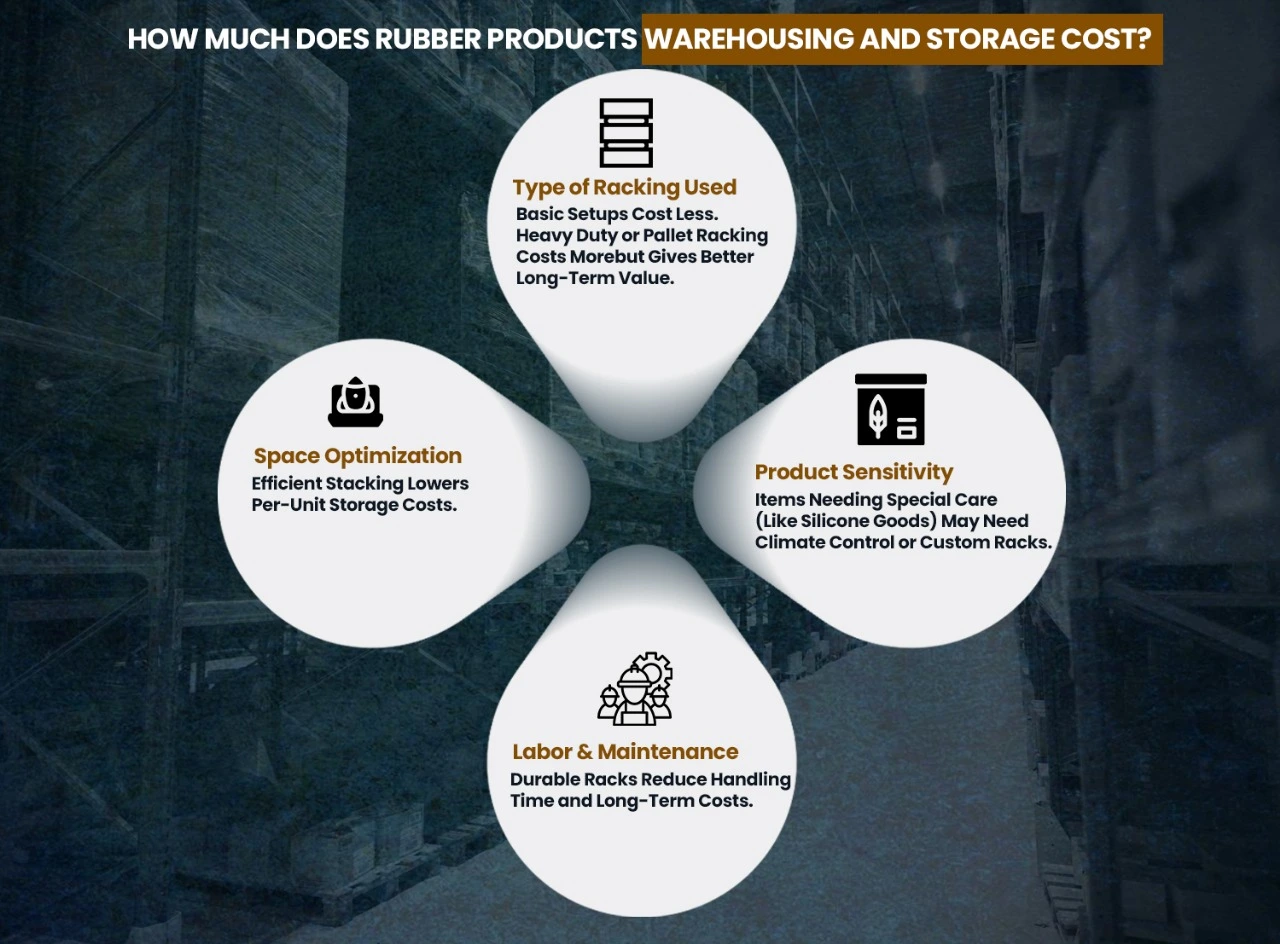

How Much Does Rubber Products Warehousing and Storage Cost?

The cost of warehousing rubber products depends heavily on the warehouse racking system in place, the space utilized, and the type of rubber items being stored. For instance, storing small items like O-rings or rubber seals requires less space than bulkier items like rubber mats or industrial silicone sheets.

- Type of Racking Used

Basic racking and storage setups are cheaper, while heavy-duty industrial racking or pallet warehouse racking may have higher initial costs but offer better ROI over time.

- Product Sensitivity

Rubber products that require special handling or environmental control (e.g., silicone-based goods) may need specialized warehouse storage racks or temperature-controlled areas.

- Labor & Maintenance

Well-maintained industrial storage racks reduce damage and labor time, lowering long-term operational costs.

- Space Optimization

Efficient warehouse racking maximizes cubic space, helping reduce per-unit storage costs.

Find the Best Heavy Duty Rubber Products That Are Easily Maintainable

- Resistant to Compression & Deformation

- Suitable for long-term stacking on pallet racking industrial systems

- Low Surface Maintenance

- Dust-resistant finishes on items like rubber mats and sleeves reduce the need for frequent cleaning

- Versatile Sizing

- Our products are compatible with standard industrial warehouse racking and commercial racking setups

- Packaging Options

- We offer bulk and customized packaging that aligns with your storage racking system for smooth loading and retrieval

Whether you’re storing silicone sleeves, gaskets, or bulk rubber sheets, DeePee Rubber’s products are engineered to stay in shape and maintain integrity over time—making them the ideal choice for structured warehouse racking.

Conclusion

Frequently Asked Questions (FAQs)

Racking in warehousing refers to the use of structured shelves or frameworks to store goods vertically. It’s essential for space efficiency and safety in modern storage operations.

There are several, including selective pallet racks, cantilever racks, push-back racks, drive-in racks, and carton flow racks—each suited to different storage needs.

While sizes vary by product and rack type, a typical bay size for pallet warehouse racking is 8 to 12 feet wide, 4 feet deep, and 8 to 16 feet tall.