Introduction

In high-speed, high-pressure machinery, seal performance can make or break long-term reliability. Wave seals offer an innovative sealing solution that balances strength, flexibility, and thermal resistance. This blog explores the benefits of using wave seals in mechanical systems—and why choosing quality from trusted rubber products manufacturers like Deepee Rubber matters. The benefits of using wave seals extend far beyond basic sealing—they optimize uptime, efficiency, and overall equipment reliability.

What Are Wave Seals and How They Work

- Design: Multi-wave profile compresses evenly under pressure

- Application: Used in automotive, heavy equipment, pumps, and gearboxes

- Edge: Works well in misaligned or thermally unstable systems

The benefits of using wave seals here include lower friction, better flexibility, and the ability to perform in variable motion scenarios. When precision matters, wave seals in machinery outperform conventional sealing elements.

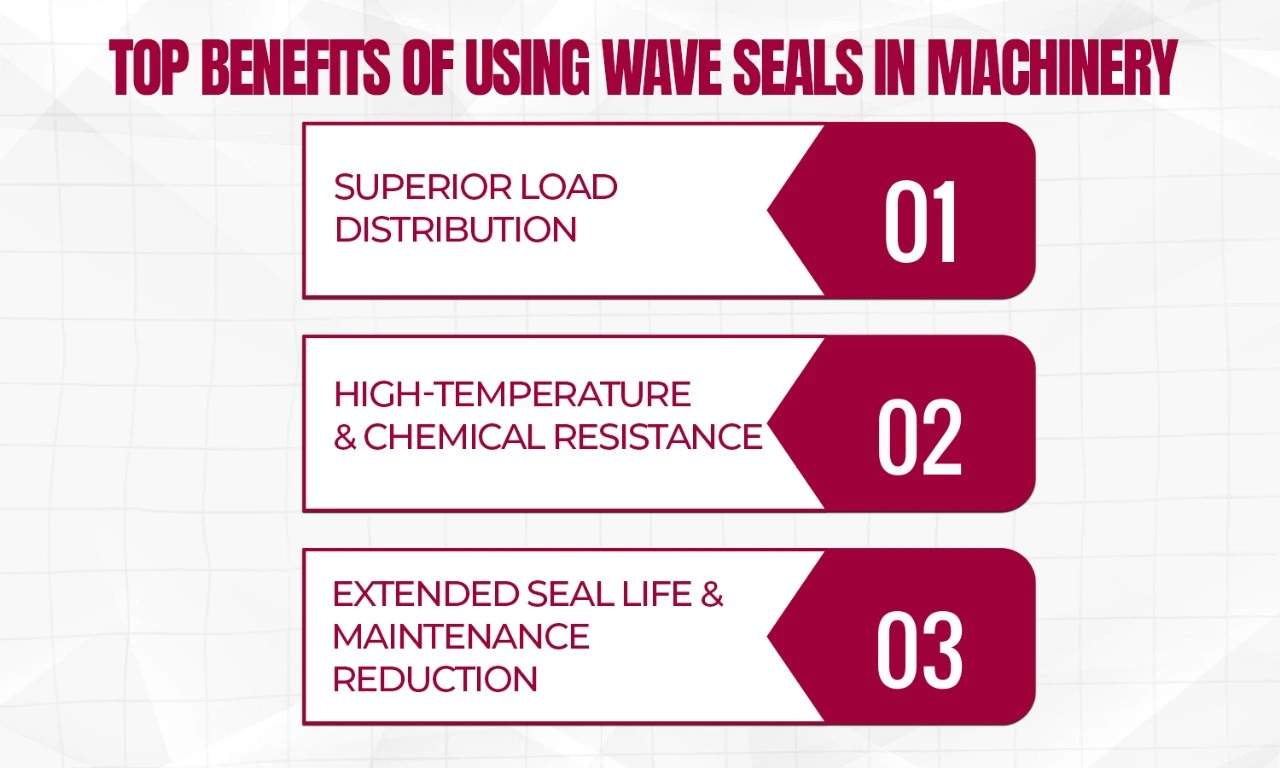

Top Benefits of Using Wave Seals in Machinery

Their unique design helps reduce friction and heat buildup, which means less wear, fewer replacements, and less unplanned downtime. If you’re aiming for longer seal life, fewer shutdowns, and better overall equipment health, the benefits of using wave seals are clear.

Deepee: The Best Wave Seals in Machinery

- ISO-compliant manufacturing processes

- Material options suited for varied industries

- Application-specific design consultations

When you prioritize the benefits of using wave seals, choosing the right manufacturing partner becomes critical. If you’re sourcing high-performance industrial rubber products, Deepee delivers engineered reliability backed by years of sealing expertise.

Key Takeaways

- Wave seals provide better sealing under dynamic and thermal stress

- Their geometry supports long-term equipment reliability

- Deepee Rubber offers custom-engineered solutions for industrial-grade needs

- The benefits of using wave seals include reduced downtime and extended life span

- Trust Deepee, the best rubber manufacturers in India, for your next wave seal procurement