Introduction

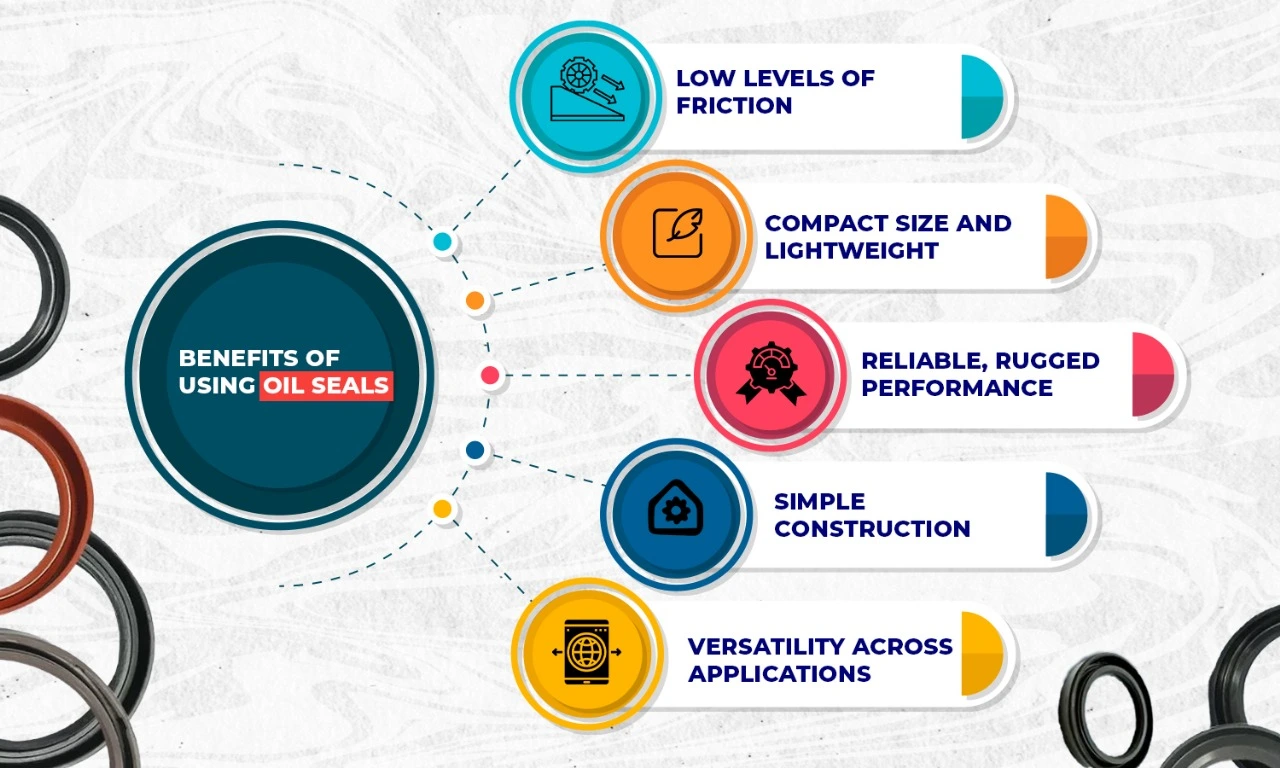

Oil seals may seem like small components, but their impact on machinery performance is significant. From preventing lubricant leakage to blocking contaminants, oil seals play a vital role in extending equipment life. In this blog, we’ll walk you through the top 5 benefits of using oil seals in industrial environments, helping you understand their value in maintaining reliability and efficiency.

What Is an Oil Seal?

Before diving into the benefits of using oil seals, it’s essential to understand what they are. An oil seal also known as a rotary shaft seal is a component that protects mechanical systems by sealing lubricants in and keeping harmful elements out. These seals are available in various oil seal types, each suited to specific applications across automotive, manufacturing, and heavy equipment industries.

Low Levels of Friction

Compact Size and Lightweight

Another major benefit of using oil seals is their compact and lightweight design. Despite their small footprint, they provide efficient sealing performance in high speed and high-pressure environments. With a variety of oil seal sizes available, manufacturers can easily select seals that fit their machinery’s specific needs without adding unnecessary bulk.

Reliable, Rugged Performance

When it comes to industrial environments, durability matters. The benefits of using oil seals include their rugged design, which withstands extreme temperatures, contaminants, and continuous operation. Whether it’s dust, moisture, or abrasive particles, quality oil seals offer dependable protection against breakdowns.

Simple Construction

A notable benefit of using oil seals is their straightforward design. Most oil seals feature a flexible lip, a metal case, and a tensioning spring simple yet effective in preventing leakage. This simplicity allows for easy installation and reduces downtime during maintenance or replacements.

Why Should You Choose DeePee Rubber for Your Oil Seal Needs?

If you’re seeking oil seals that deliver long-term value and performance, DeePee Rubber is a trusted choice. With a wide range of oil seal types and custom manufacturing capabilities, we ensure you get seals that meet the exact needs of your machinery. Our precision-engineered components reflect our commitment to quality and industrial reliability.

Key Takeaways

- The benefits of using oil seals include reduced friction, durability, and leak prevention.

- Their compact, simple design makes them easy to install and maintain.

- Available in various oil seal types and sizes, these components support a wide range of applications.

- Oil seals help protect machinery from contaminants and wear.

- DeePee Rubber, the best rubber manufacturers, offers customized sealing solutions backed by technical expertise.