Introduction

Choosing the right oil seal is crucial for maintaining the efficiency, safety, and lifespan of your industrial equipment. A poorly matched seal can lead to frequent breakdowns, fluid leaks, and costly downtime. This guide offers practical advice on choosing the best oil seals, so your operations remain smooth and interruption-free. Whether you’re sourcing for OEM needs or equipment maintenance, choosing the best oil seals ensures reliability and long-term savings.

Why Choosing the Right Oil Seal Matters

Oil seals play a vital role in sealing lubricants and blocking contaminants from entering sensitive mechanical areas. When you choose the wrong seal, you risk:

- Equipment overheating or seizing

- Reduced component life cycles

- Reduced component life cycles Maintenance frequency and cost surges

Oil seal selection is not just about dimensions—it’s about material compatibility, operating temperature, speed, and pressure. Choosing the best oil seals means selecting based on real-world application needs and performance expectations.

Key Factors to Consider When Selecting Oil Seals for Your Industry

For optimal results, follow these selection factors:

- Material Compatibility: Match the seal material (e.g., NBR, FKM, or Silicone) with the fluid and temperature environment.

- Oil Seal Dimensions: Ensure exact shaft diameter and housing bore for a perfect fit.

- Operating Conditions: Consider temperature, RPM, and pressure range.

- Application Type: Static vs. dynamic, axial vs. radial sealing—understand the stress profile.

A reliable oil seal manufacturer will offer selection support based on your use case, ensuring higher reliability and longer service life. Choosing the best oil seals also involves checking test certifications and sourcing seals from trusted industry suppliers.

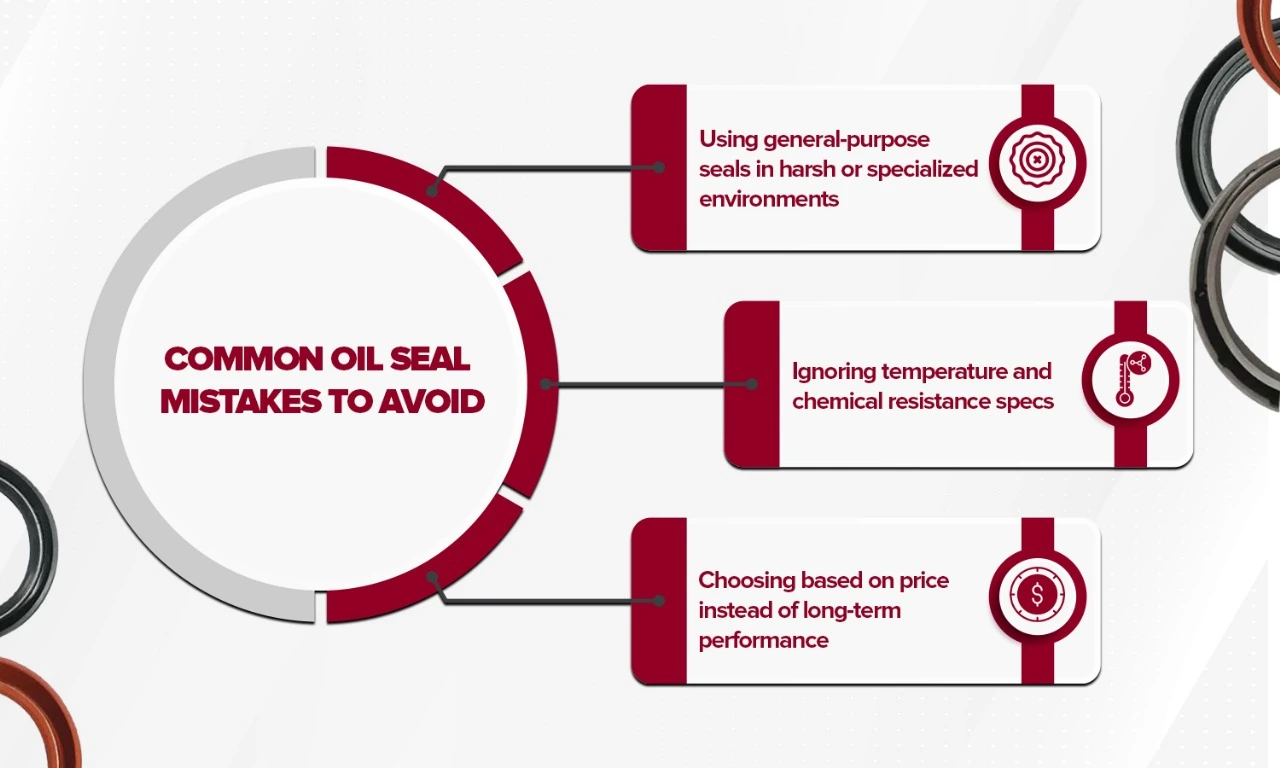

Common Mistakes to Avoid When Buying Oil Seals

Even experienced engineers can make errors when in a rush or when specs are unclear. Avoid these pitfalls:

- Using general-purpose seals in specialized environments

- Ignoring temperature/chemical exposure ratings

- Selecting seals without consulting a complete oil seal guide

- Choosing based only on cost rather than long-term durability

Mistakes in oil seal compatibility lead to frequent replacements and safety risks. Always verify specs and sourcing standards. Choosing the best oil seals means prioritizing performance over short-term savings.

Conclusion

Selecting the right oil seal is a blend of material science, mechanical understanding, and application context. With accurate oil seal selection, you’ll reduce failure rates, extend machine life, and ensure optimal sealing performance. Deepee Rubber’s engineering team can help recommend the ideal solution based on your machinery specs and operational needs. If you’re committed to choosing the best oil seals, expert guidance and data-backed decisions are non-negotiable.

Key Takeaways

- Choosing the best oil seals prevents leaks and component failures

- Match materials and specs to your equipment’s operating environment

- Avoid low-cost seals that may fail under stress or heat

- Refer to a technical oil seal guide or manufacturer for selection support

- Deepee Rubber provides expert-backed seals for varied industrial needs

Frequently Asked Question

Trusted industrial brands like Deepee Rubber offer tested, high-performance oil seals with engineering-grade materials and custom options.

It depends on the application. NBR suits general use, FKM for high heat and chemical exposure, and Silicone for food-grade or extreme cold conditions.

Replacement depends on usage and conditions, but routine checks every 6–12 months are recommended to avoid failures.