Introduction

From preventing leaks to ensuring smooth mechanical performance, industrial applications of oil seals are critical across countless sectors. Whether in automotive, heavy machinery, or large-scale manufacturing, these small components play a big role in protecting systems from contaminants, retaining lubricants, and reducing wear. In this article, we explore how oil seals keep industries running reliably and why selecting the right one matters.

Where Are Oil Seals Used in Everyday Industry?

The industrial applications of oil seals span across multiple domains—from oil seals in manufacturing to robotics and assembly lines. In rotating shafts and hydraulic systems, oil seals prevent fluid leaks, protect bearings, and block contaminants from entering mechanical systems. They are found in motors, pumps, gearboxes, and even turbines anywhere moving parts require controlled lubrication.

This wide application makes understanding different oil seal types essential, as each type serves a specific function depending on temperature, speed, and pressure requirements.

This wide application makes understanding different oil seal types essential, as each type serves a specific function depending on temperature, speed, and pressure requirements.

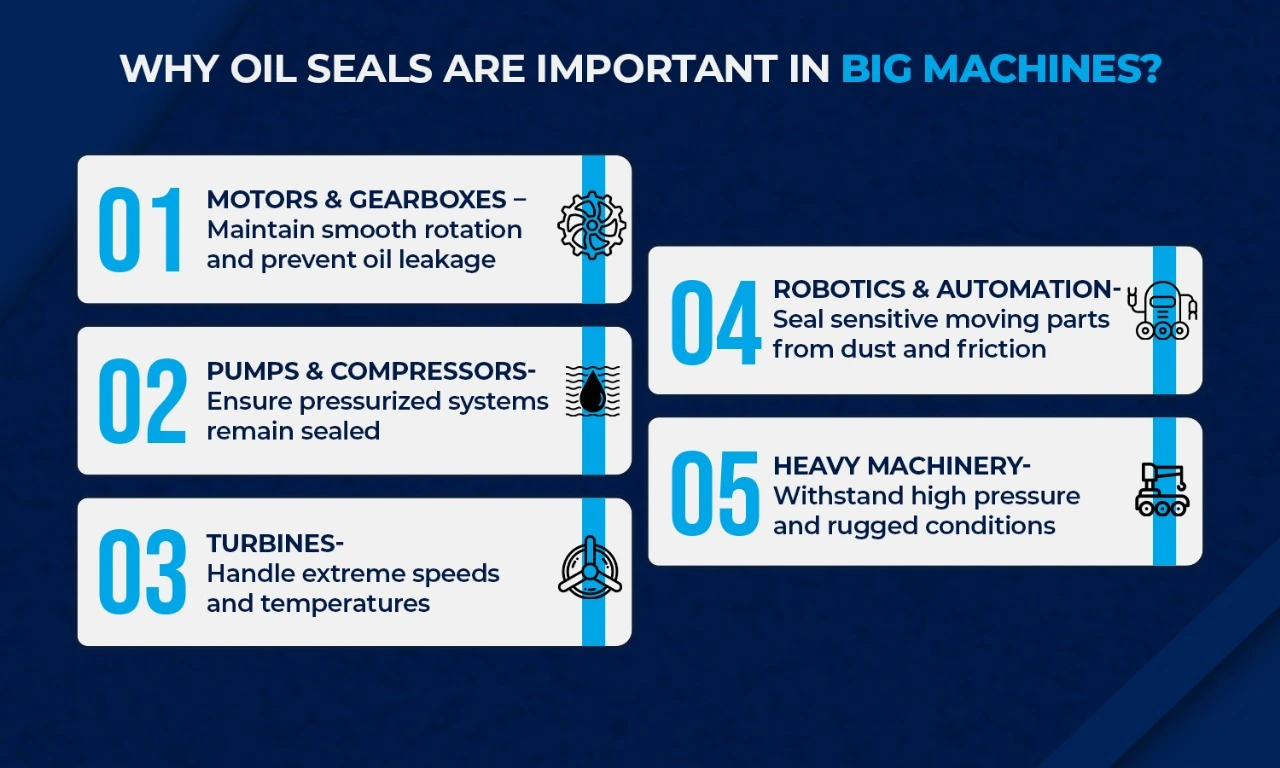

Why Oil Seals Are Important in Big Machines?

In heavy-duty equipment, oil seals for heavy machinery are designed to withstand extreme conditions. These seals prevent critical failures by retaining high-viscosity lubricants and withstanding large axial and radial loads. For instance, excavators, mining equipment, and cranes depend on oil seals to maintain pressure and lubrication in hydraulic systems.

These use-cases clearly showcase the importance of industrial sealing solutions that are durable, heat-resistant, and capable of performing in high-load conditions.

How Oil Seals Protect Machinery in Manufacturing Plants?

In precision-driven settings, such as oil seals in automotive production lines, even a minor leak can lead to downtime, component failure, or poor product output. That’s why oil seals in manufacturing environments must meet high standards of performance and consistency.

From CNC machines to robotic arms, industrial applications of oil seals prevent dust, chemicals, and debris from interfering with sensitive components. These seals are engineered to sustain high RPMs, fluctuating pressures, and frequent usage cycles without degradation.

Conclusion

The industrial applications of oil seals are both wide-ranging and deeply critical. Without these components, even the most advanced machines would face rapid wear, unexpected leaks, and costly downtime. Whether you’re dealing with oil seals in automotive, manufacturing, or heavy machinery, selecting the right type and material is vital.

Key Takeaways

- Industrial applications of oil seals include automotive, manufacturing, and heavy machinery.

- They protect against contaminants, retain lubricants, and ensure mechanical efficiency.

- Choosing the right oil seal types enhances system life and reduces operational risk.

- Oil seals in manufacturing must resist wear, pressure, and contaminants.

- For rugged use, rely on specialized oil seals for heavy machinery

Frequently Asked Question

Oil seals are extensively used in automotive, aerospace, heavy machinery, agriculture, and industrial manufacturing.

Consider temperature, pressure, speed, and the type of fluid or contamination exposure.

To retain lubricant, prevent leakage, and block contaminants from entering the mechanical system.