Introduction

Spiral wound gaskets are one of the most reliable sealing solutions used in demanding industrial environments. Designed for use in high-pressure and high-temperature systems, these gaskets are a preferred choice among engineers and maintenance heads. In this blog, we highlight the key advantages of spiral wound gaskets, their applications, and why they’re trusted by top spiral wound gasket manufacturers.

What Are Spiral Wound Gaskets?

Spiral wound gaskets are composite gaskets that combine the flexibility of soft filler material (like graphite or PTFE) with the strength of a metallic winding. They’re designed to withstand temperature spikes, pressure changes, and corrosive media. Leading spiral wound gasket suppliers recommend them for flange joints in petrochemical, power, and process industries.

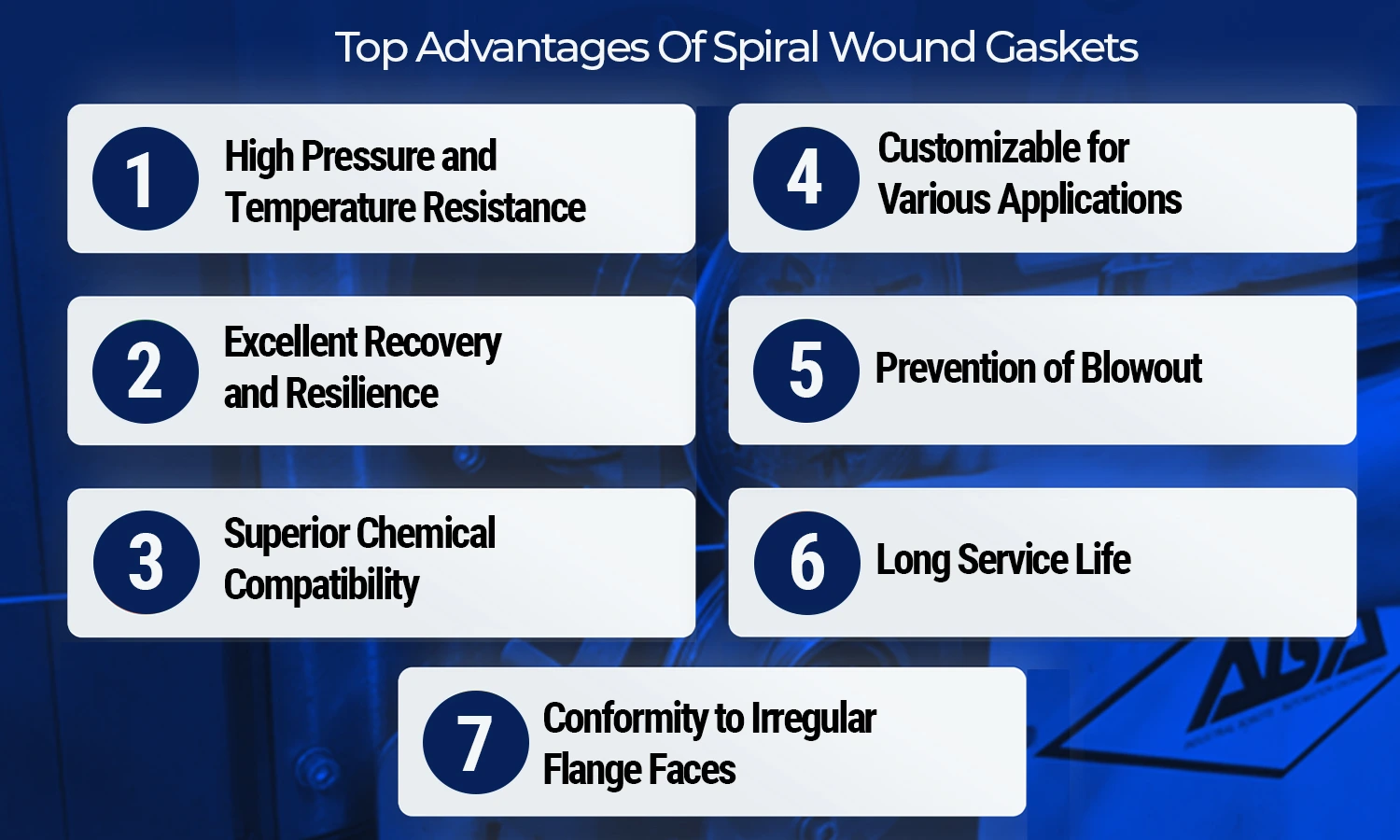

Top Advantages Of Spiral Wound Gaskets

1. High Pressure and Temperature Resistance

2. Excellent Recovery and Resilience

3. Superior Chemical Compatibility

4. Customizable for Various Applications

They’re available in various diameters, thicknesses, and filler materials. This flexibility ensures compatibility with multiple flange types and standards.

5. Prevention of Blowout

Thanks to the reinforcement of the metal winding, spiral wound gaskets are highly resistant to blowouts—even under sudden pressure spikes.

6. Long Service Life

Their robust construction ensures long-lasting performance, reducing the need for frequent replacements and lowering maintenance costs.

7. Conformity to Irregular Flange Faces

These gaskets adapt to uneven or worn flange surfaces, ensuring a tight and reliable seal even when surface conditions aren’t ideal.

Looking for Reliable Spiral Wound Gaskets? DeePee Has You Covered

At Deepee Rubber, a trusted rubber products supplier and provider of industrial rubber products, we offer high-performance spiral wound gaskets that meet international quality standards. Whether you’re sourcing for oil & gas, pharma, or chemical processing, our solutions are backed by material traceability, quality control, and engineering support. As one of India’s top spiral wound gasket manufacturers, we help clients meet sealing challenges with confidence.

Key Takeaways

- Spiral wound gaskets handle extreme pressure, temperature, and corrosive environments

- Their design ensures resilience, longevity, and conformity to surface variations

- Deepee Rubber supplies customizable spiral wound gaskets for critical systems