Introduction

Wave seals are increasingly becoming essential components in modern industrial systems. Known for their advanced sealing geometry and resilience, they are designed to handle thermal changes, pressure shifts, and motion-heavy operations. This blog focuses on the primary uses of wave seals across different industrial equipment and why they are the go-to solution for many engineers and OEMs. Understanding the uses of wave seals can help optimize equipment performance and reduce maintenance costs.

What Are Wave Seals?

Wave seals are compact, elastomer-based sealing components engineered to maintain uniform sealing pressure in both static and dynamic environments. Their unique multi-wave profile ensures tight contact even under axial movement or misalignment.

- Category: A type of dynamic sealing element

- Advantage: Offers better performance than traditional flat gaskets or O-rings

- Usage Spectrum: From compressors to gearboxes, their application is wide-ranging

The uses of wave seals go far beyond basic sealing. They’re engineered to handle real-world mechanical stress, fluid exposure, and speed variation.

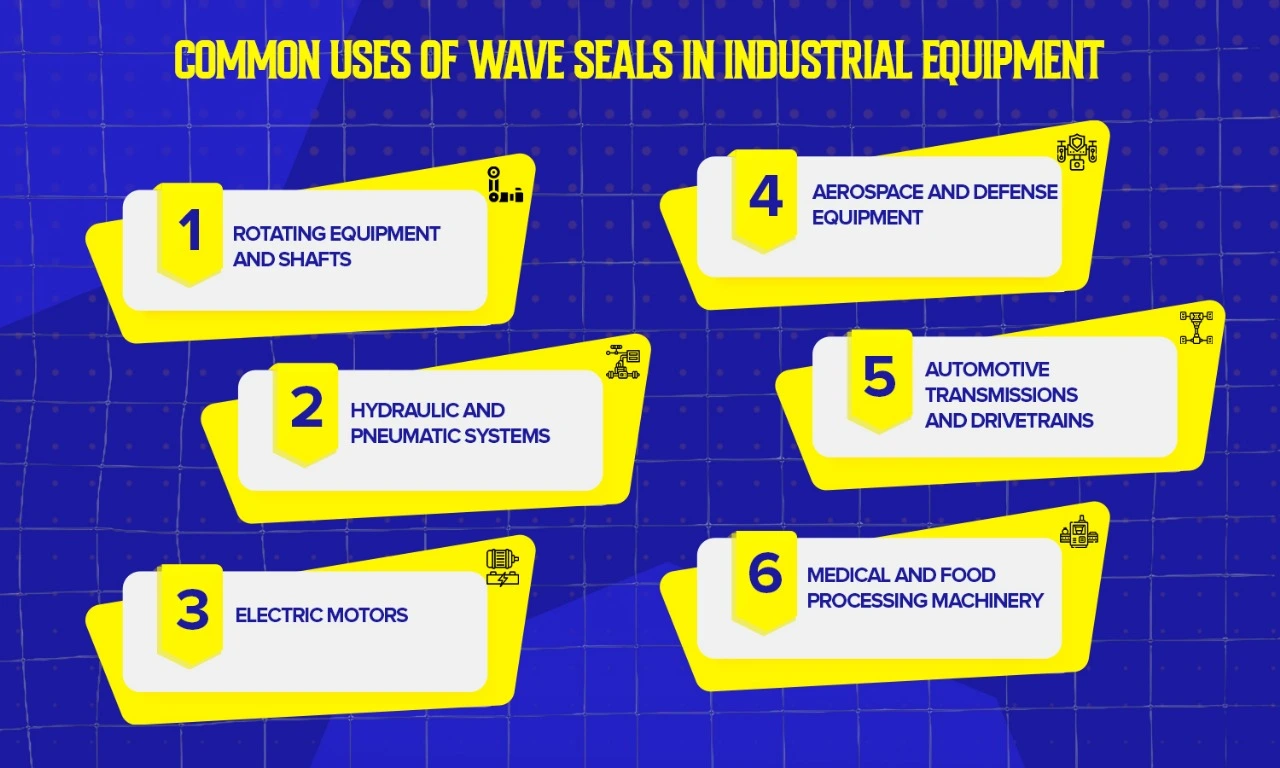

Common Uses Of Wave Seals In Industrial Equipment

a. Rotating Equipment and Shafts

Wave seals are highly effective in dynamic shaft systems such as turbines, motors, and pumps. Their flexible structure accommodates movement while maintaining a tight seal. Among the most common uses of wave seals, this one ensures equipment runs without leaks or pressure drops.

b. Hydraulic and Pneumatic Systems

In fluid-powered machines, wave seals prevent oil or air leaks under high pressure, making them an ideal choice for maintaining system efficiency and control. These are critical uses of wave seals in maintaining operational safety and energy efficiency.

c. Electric Motors

In electric motors, wave seals block dust and moisture from entering motor housings while also managing friction at high speeds. One of the essential uses of wave seals in electric systems is longevity through minimal wear.

d. Aerospace and Defense Equipment

With stringent demands for performance and safety, wave seals are used in landing gear assemblies, actuators, and mission-critical controls. These specialized uses of wave seals highlight their reliability in extreme conditions.

e. Automotive Transmissions and Drivetrains

Wave seals offer excellent sealing in rotating drivetrain components, preventing lubricant loss and contamination. These are everyday uses of wave seals in vehicular systems that face vibration and thermal exposure.

f. Medical and Food Processing Machinery

Their ability to maintain hygienic conditions while resisting high temperatures and cleaning agents makes them suitable for regulated environments. Hygienic and compliant uses of wave seals in this segment improve safety and product integrity.

ALSO READ : Top Benefits Of Using Wave Seals In Machinery

Contact Deepee Rubber For More Information About Wave Seals In Industrial Equipment

As one of the most trusted rubber products manufacturers, Deepee Rubber specializes in precision-engineered industrial rubber products including wave seals. Whether you’re designing for high-speed industrial machinery or temperature-sensitive food-grade applications, our team can guide you with custom sealing solutions.

- Design consultation for your specific machinery

- Industry-grade material selection support

- Proven sealing performance across sectors

For tailored advice on the uses of wave seals, reach out to our technical experts today.

Key Takeaways

- Wave seals provide reliable dynamic sealing across multiple industries.

- Ideal for rotating shafts, hydraulic systems, motors, and food-grade applications.

- Help reduce leakage, friction, and maintenance.

- Deepee Rubber offers high-quality solutions for OEM and retrofit use.

- The uses of wave seals span across regulated, heavy-duty, and high-performance sectors.

Frequently Asked Question

Wave seals are typically manufactured using elastomers like NBR, FKM, and PTFE, based on application needs.

Some applications may use lubrication to reduce wear, but many wave seals are designed for dry running depending on the system setup.

Yes, wave seals are engineered for dynamic sealing and are commonly used in high-speed equipment like electric motors and turbines.