In Industries Dealing With Rubber Components, Proper Storage Plays a Direct Role in Maintaining Product Quality and Reducing Waste. This Warehouse Racking Guide Outlines How to Store Rubber Materials Safely and Efficiently. With the Right Racking Strategies, You Can Reduce Material Degradation, Simplify Inventory Access, and Ensure Compliance With Safety Standards.

What Is a Warehouse? What Is Warehouse Racking?

A Warehouse Is a Dedicated Space Used for Storing Raw Materials, Semi-finished Goods, or Final Products. Warehouse Racking Refers to the Structured System Used to Stack and Organize These Materials for Easy Access and Space Optimization.

For Rubber Products Especially Those Prone to Shape Deformation, Surface Damage, or Contamination Racking Systems Help Keep Items in Controlled Environments. Without Proper Racking, Materials Like Silicone O Ring Seals or Flexible Tubings May Lose Their Functionality Over Time.

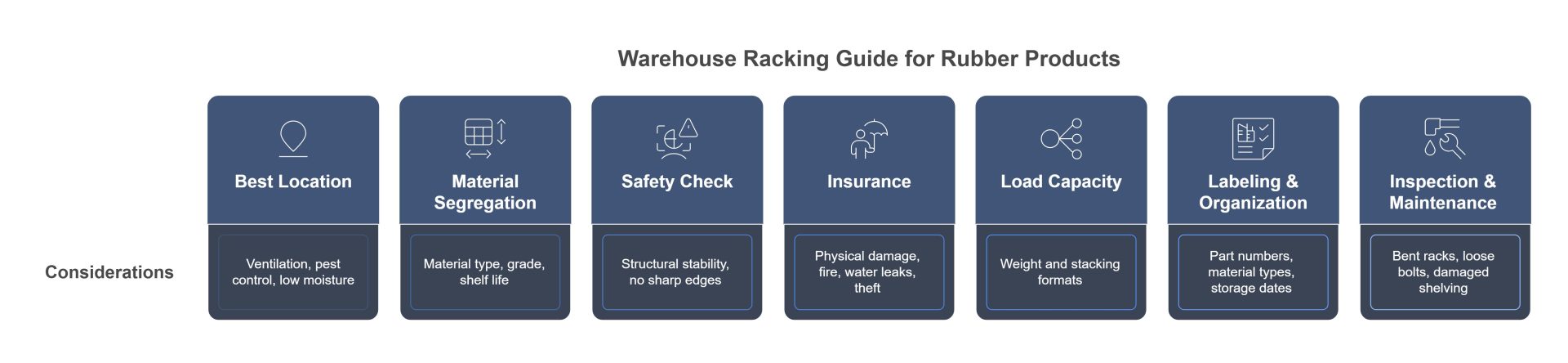

7 Essential Tips for Warehouse Racking Guide for Rubber Products

- Choose the Best Warehouse Location

Location Affects Temperature, Humidity, and Handling. To Implement a Reliable Warehouse Racking Guide, Select a Facility With Good Ventilation, Pest Control, and Low Moisture Exposure. Rubber Products Such as Silicone Rubber Tubings Can Degrade if Exposed to Direct Sunlight or Damp Environments. - Segregate the Type of Materials to Be Stored

All Rubber Isn’t the Same. You May Store Elastomers Like Viton O Rings and Natural Rubber Sheets Side by Side — But They Each Require Separate Conditions. Segregating Based on Material Type, Grade, and Shelf Life Helps Prevent Cross-Contamination and Mix-Ups in Inventory. - Safety Check Before Racking

Before Placing Rubber Products on a Rack, Check the Structural Stability of the Shelves. Ensure There Are No Sharp Edges, Exposed Metal, or Contamination Sources That Can Damage Materials. This Is Especially Important When Dealing With Soft Items Like Food Grade Rubber Sheet, Which Require Clean, Non-abrasive Surfaces for Contact. - Insure Your Materials

Rubber Components Can Represent Significant Value in Bulk. As Part of Your Warehouse Racking Guide, Make Sure Materials Are Insured Against Physical Damage, Fire, Water Leaks, and Theft. This Is Particularly Relevant for Large Orders Sourced From Natural Rubber Sheet Manufacturers or Custom-Molded Parts Awaiting Dispatch. - Consider Load Capacity

Rubber Products Can Be Heavy, Especially When Stored in Rolls, Bundles, or Stacked Formats. Always Calculate Load Capacity for Each Rack Level. Failing to Do So Can Compromise Rack Integrity and Lead To Product Deformation — Particularly in Materials Like Silicone That Are Soft and Impressionable. - Label and Organize Clearly

Label Racks With Part Numbers, Material Types, and Storage Dates. This Reduces Picking Errors and Ensures Stock Rotation Based on FIFO (First In, First Out). Well-Organized Shelves Also Allow Faster Quality Checks and Inventory Audits Without Disrupting the Entire System. - Inspect and Maintain Regularly

A Warehouse Racking System Is Not a One-Time Setup. Periodic Inspection Ensures That Your Structure Remains Fit for Storage. Bent Racks, Loose Bolts, or Damaged Shelving Must Be Addressed Immediately. Maintaining Rubber Racking Standards Will Reduce Product Rejection and Help Preserve Quality Across Every Delivery.

Learned About Warehousing? Now Looking for the Best Rubber Products?

If Your Storage System Is Ready, the Next Step Is Sourcing the Right Components. Whether You Need Bulk Silicone O Ring Kits, Chemical-Resistant Viton Components, or Sheets From Natural Rubber Sheet Manufacturers, Deepee Rubber Supplies Industrial-Grade Materials for Long-Term Use. Our Range Includes Everything From General-Purpose Seals to High-Grade Sheets Tailored to Your Environment.

Frequently Asked Question

Racking Calculations Depend on Load Weight, Rack Dimensions, and Product Type. For Rubber Materials, Take Into Account Roll Weight, Stacking Height, and Shelf Flexibility to Prevent Deformation.

Setting up a Rubber Racking System Can Take a Few Hours to Several Days Depending on the Warehouse Size and Number of SKUs. Pre-planning and Segregation by Material Speeds up the Process.

Yes. Warehouse Racking Is Typically Considered a Fixed Asset as It Is a Long-Term Storage Infrastructure Investment.

Yes, Rubber Products Can Be Safely Racked When Stored Under Proper Conditions. Using This Warehouse Racking Guide Helps Avoid Deformation, Contamination, and Inventory Loss.

Key Takeaways

A Warehouse Racking Guide Helps Prevent Damage and Loss in Rubber Inventory.

Choose Well-Ventilated, Dry Storage Spaces for Rubber Goods.

Segregate Rubber Materials by Type, Such as Viton O Rings and Silicone Sheets.

Regular Inspections and Maintaining Rubber Racking Systems Help Avoid Disruptions.

Partnering With Trusted Natural Rubber Sheet Manufacturers Ensures Product Quality From the Start.

Following a Proper Warehouse Racking Guide Ensures That Rubber Components Stay Functional From the Time They Enter Your Warehouse to the Time They’re Installed. These Storage Tips Help Minimize Waste, Reduce Handling Issues, and Protect Product Integrity. For Businesses Looking To Store Rubber Parts Efficiently, the Racking Process Should Be as Planned and Precise as the Manufacturing Process Itself.